What we do

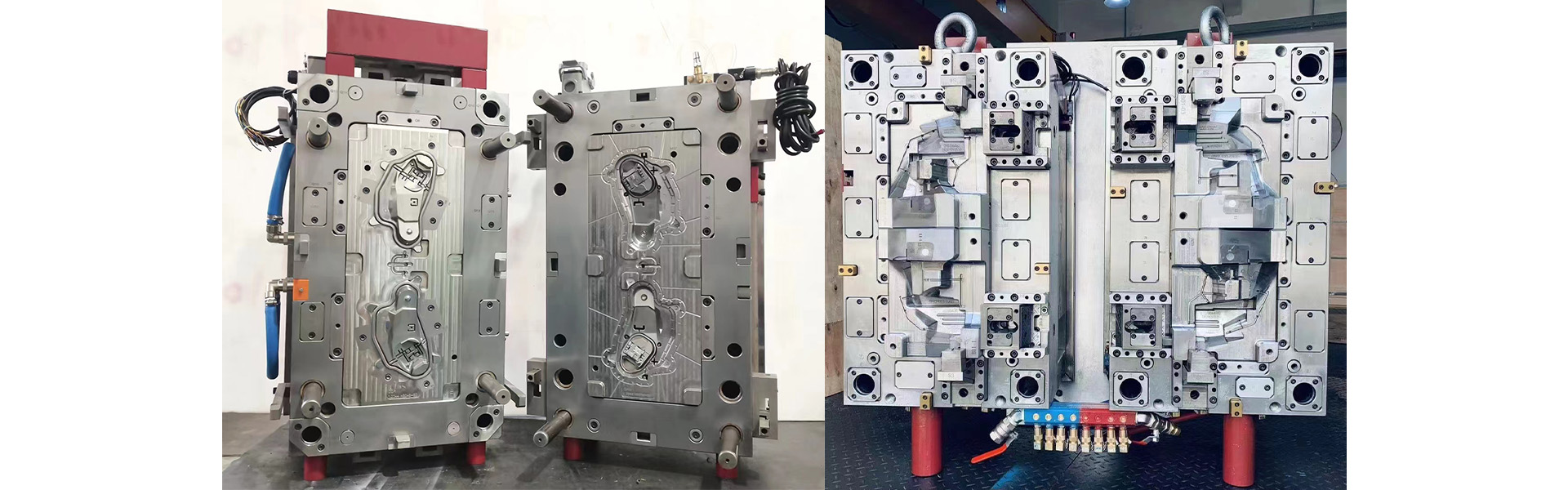

Injection Molds

JEZ Mould Plastic specialize in manufacturing high-quality plastic injection moulds and also offer injection moulding services. Our equipments are working uninterruptedly 24 hours a day. We are capable of manufacturing precise moulds with various dimensions and the complex moulds. 85% of our molds are delivered to Europe, North America. The advantages of our mold making are short cycle, high efficiency, low cost, high quality.

View detailsPlastic injection molding

We have a wide range of injection products, such as automotive products, medical&beauty, electrical & electronic, engineering industry products and aerospace products. Our injection molding materials are, such ABS, PC, PC+GF, PP, PBT, PA66, PA66+GF, PPO, PPS, PU, PE , TPE, TPU, LCP, PEI , PEEK, Ultem etc.With our vast experiences covering different fields of industries, we are sapable of offering you the right solution for your problem in top quality and on time!

View detailsPrecision Machining Component service

We provides custom precision machining components service also, that is a part of full-service for our customer. we should follow your demand to deliver quality components, and we can control tolerance in ±.01mm with metal, and plastic material is in ±.05 mm., we offer high speed CNC machining,Mirror polishing, Custom machining for mold components.Each step was strictly controled by inspection before we start to next step.

View details